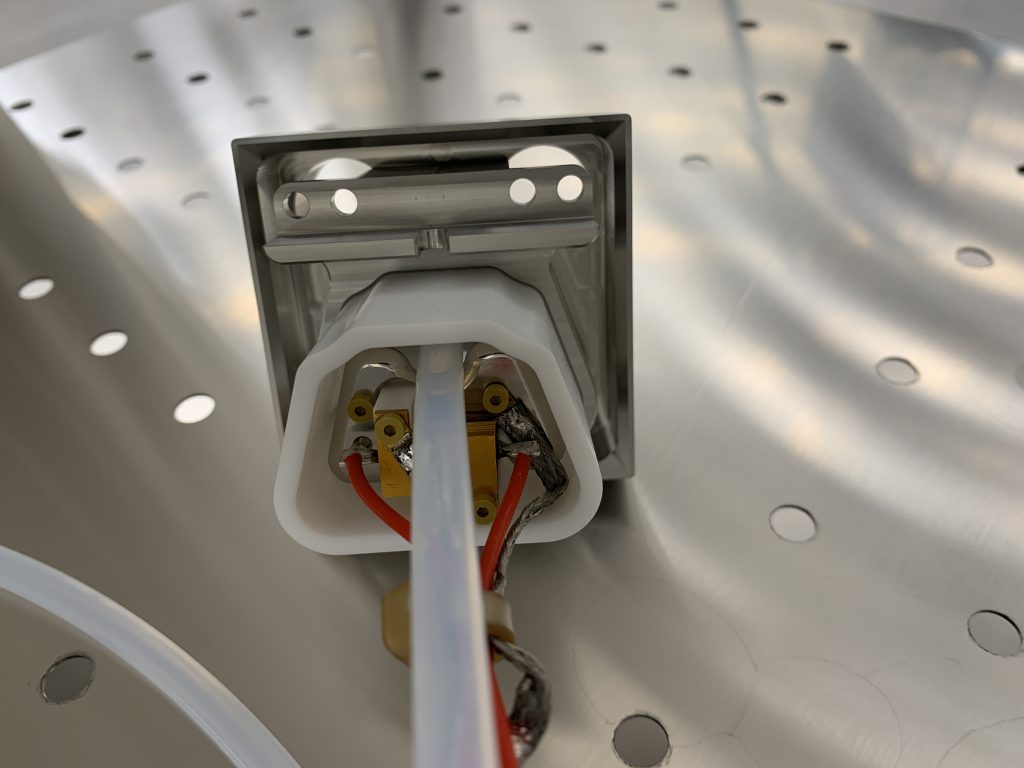

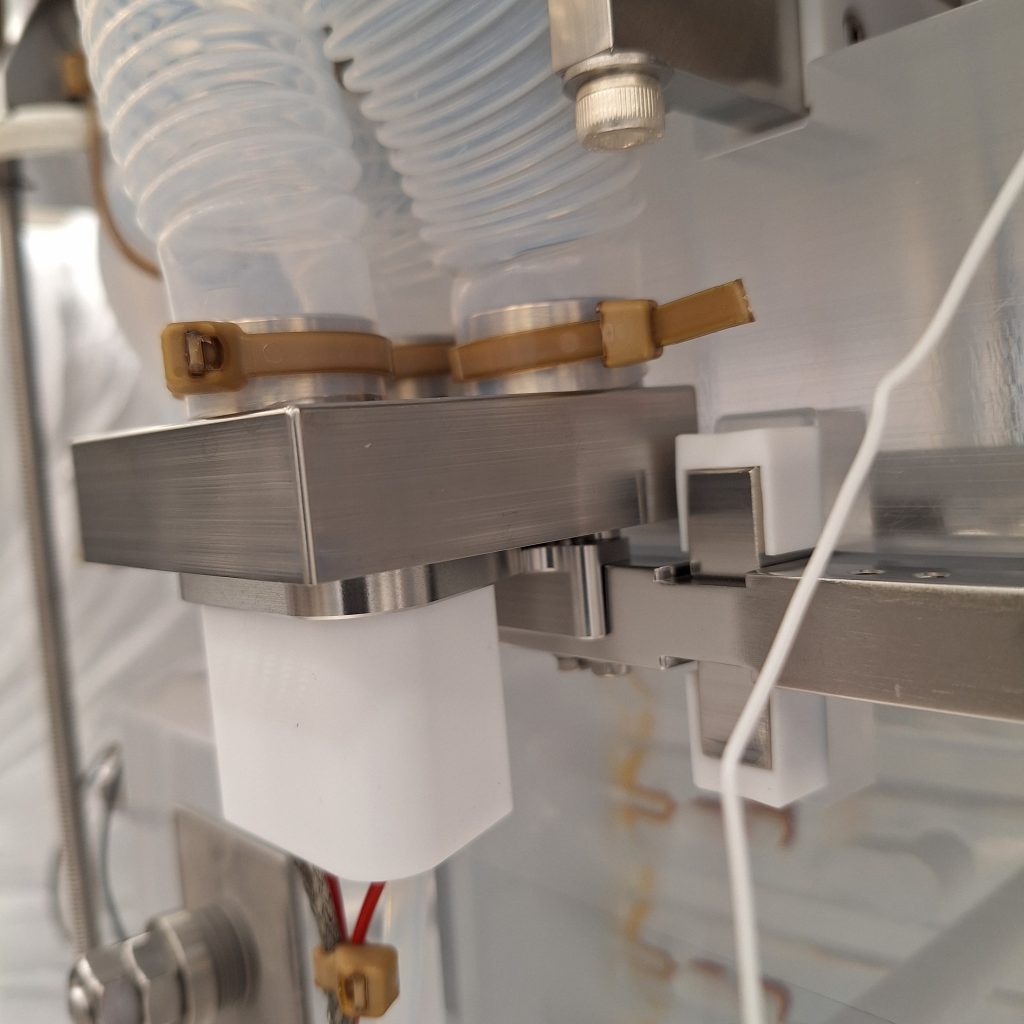

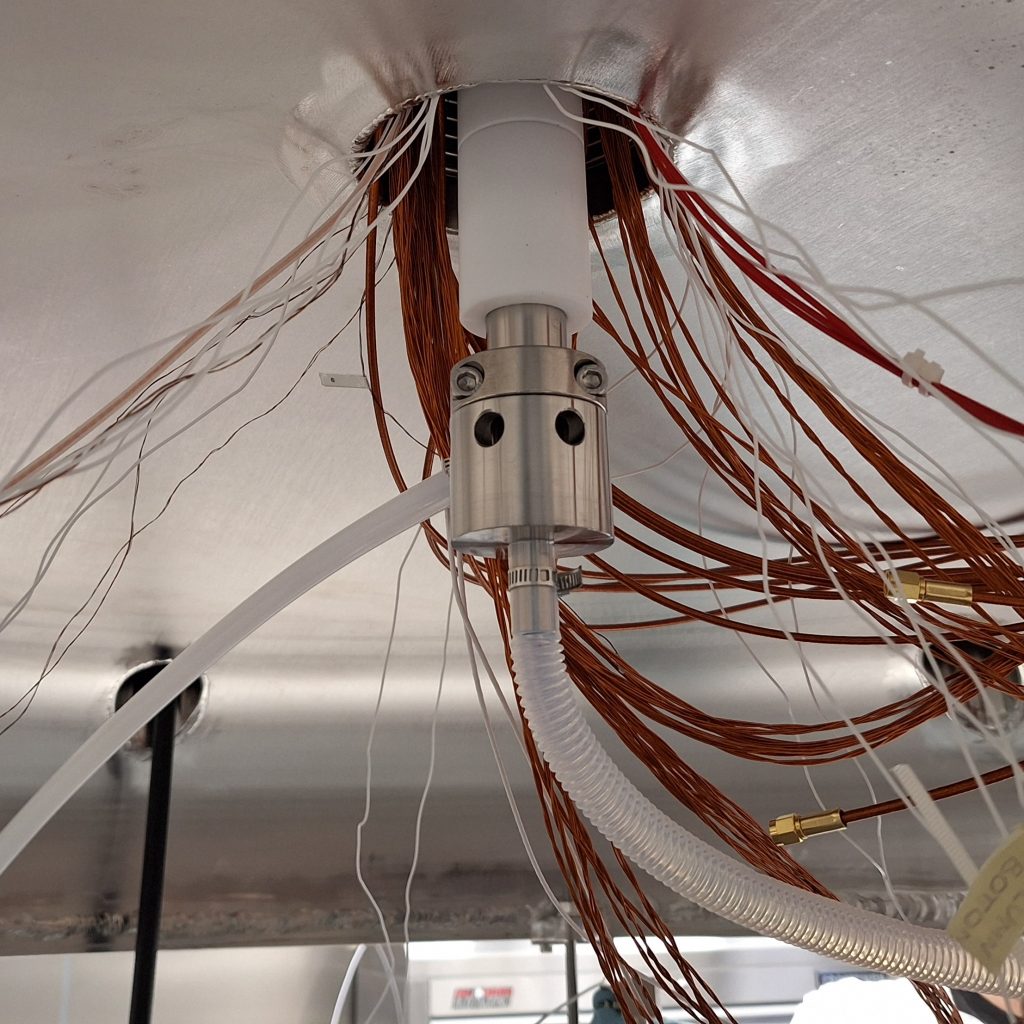

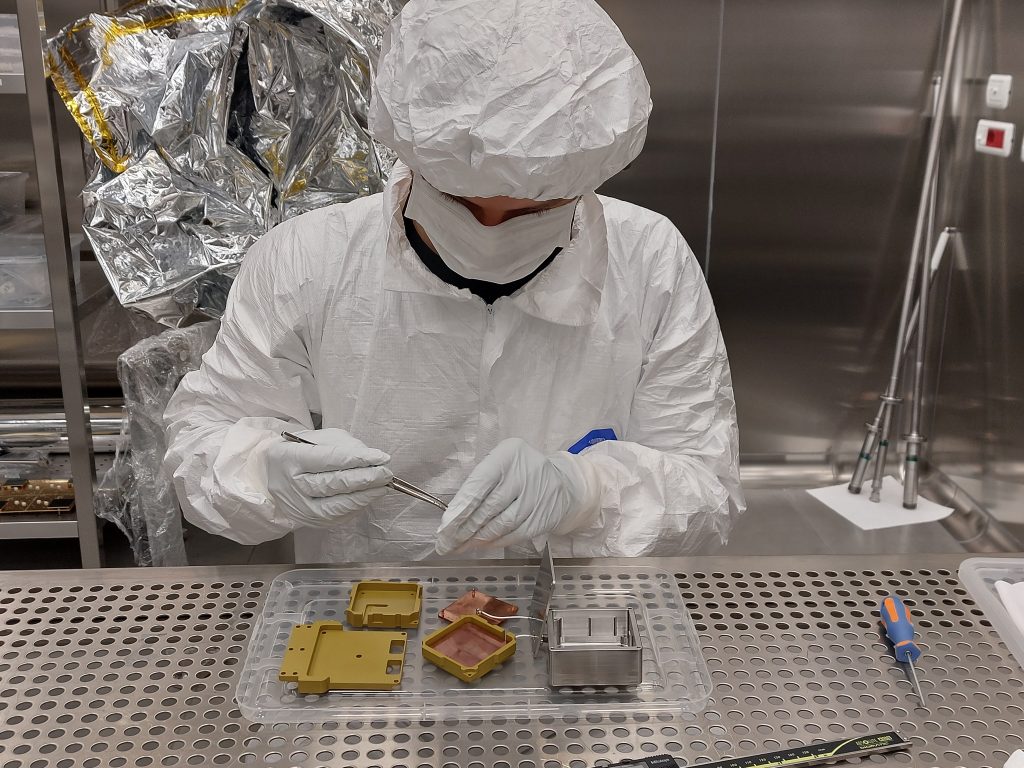

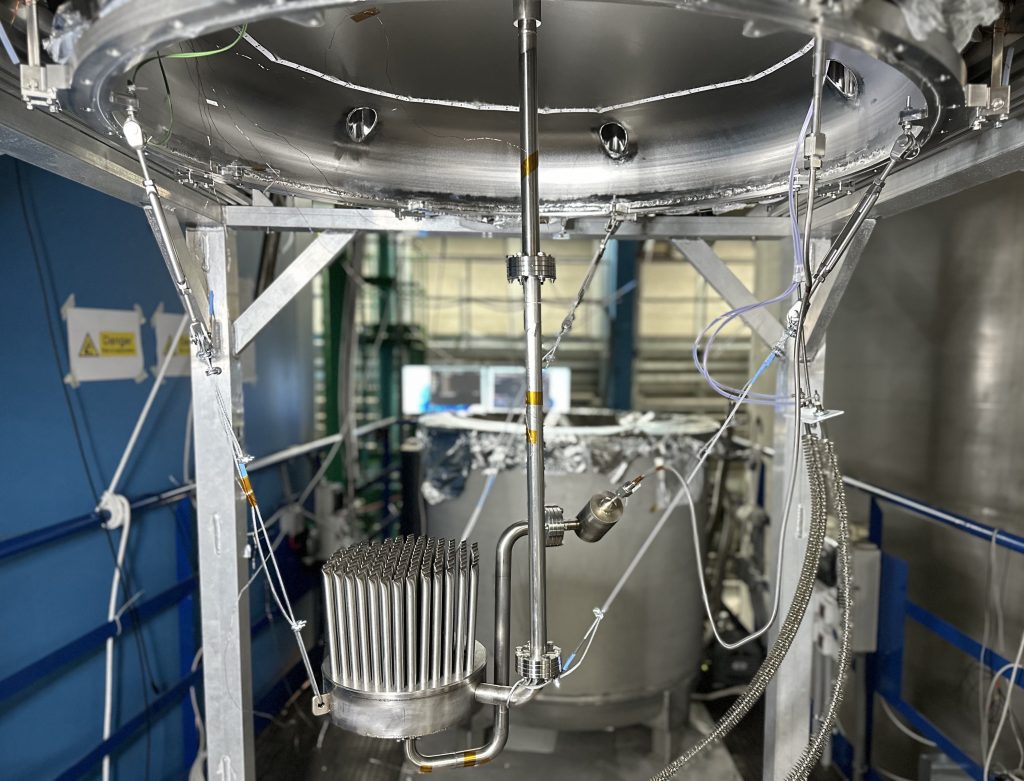

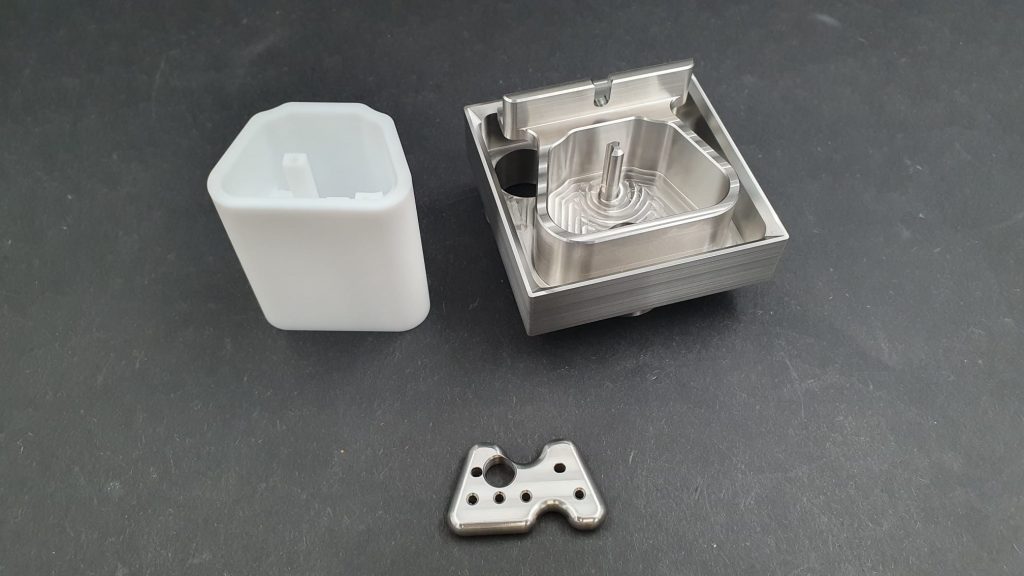

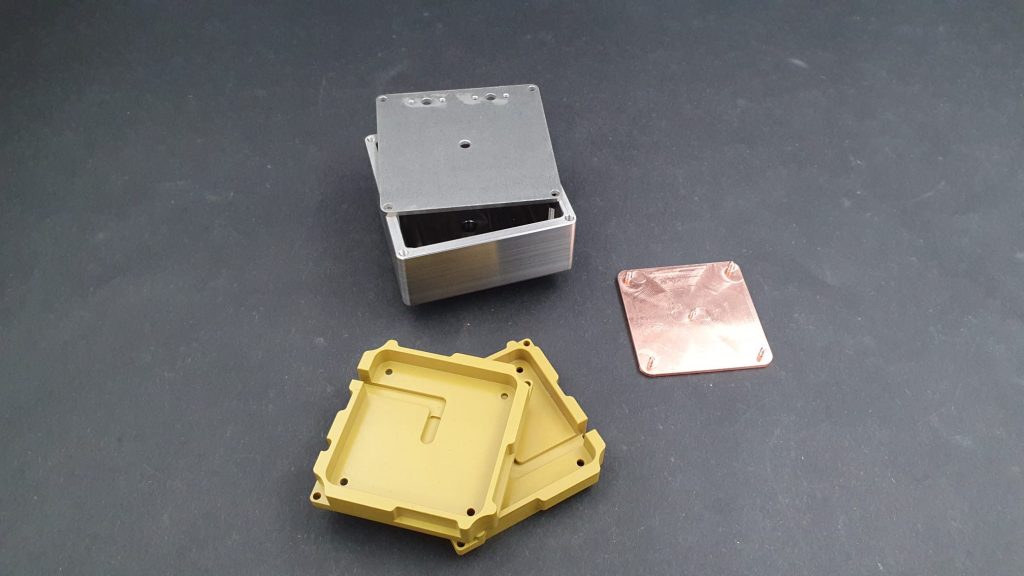

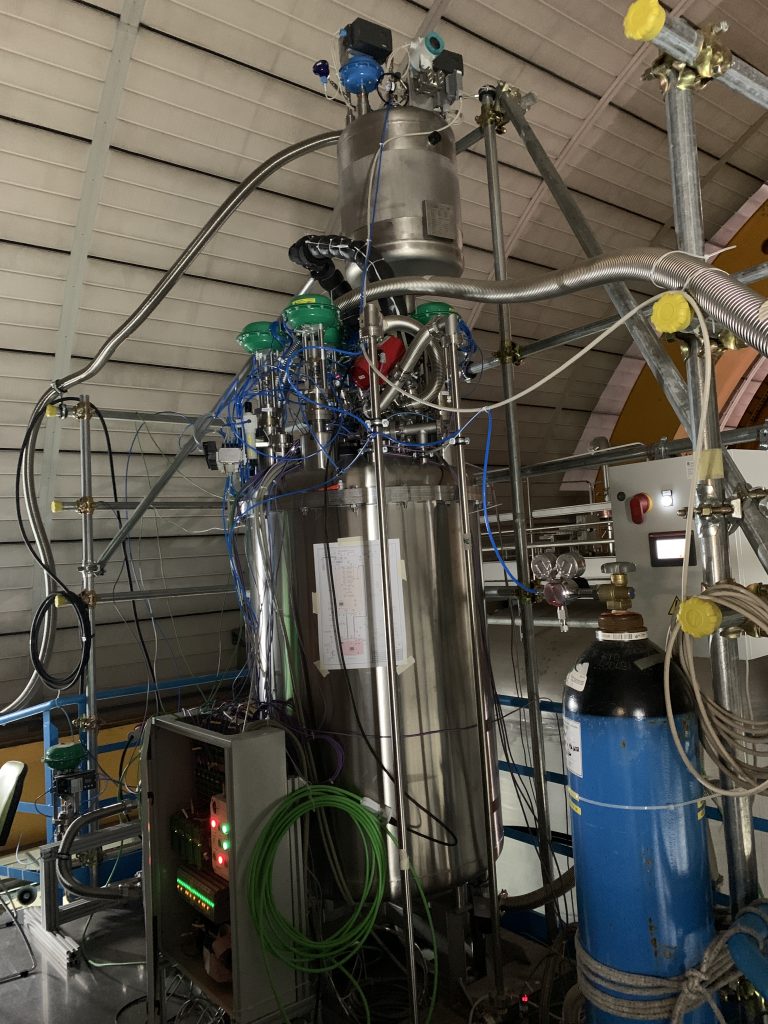

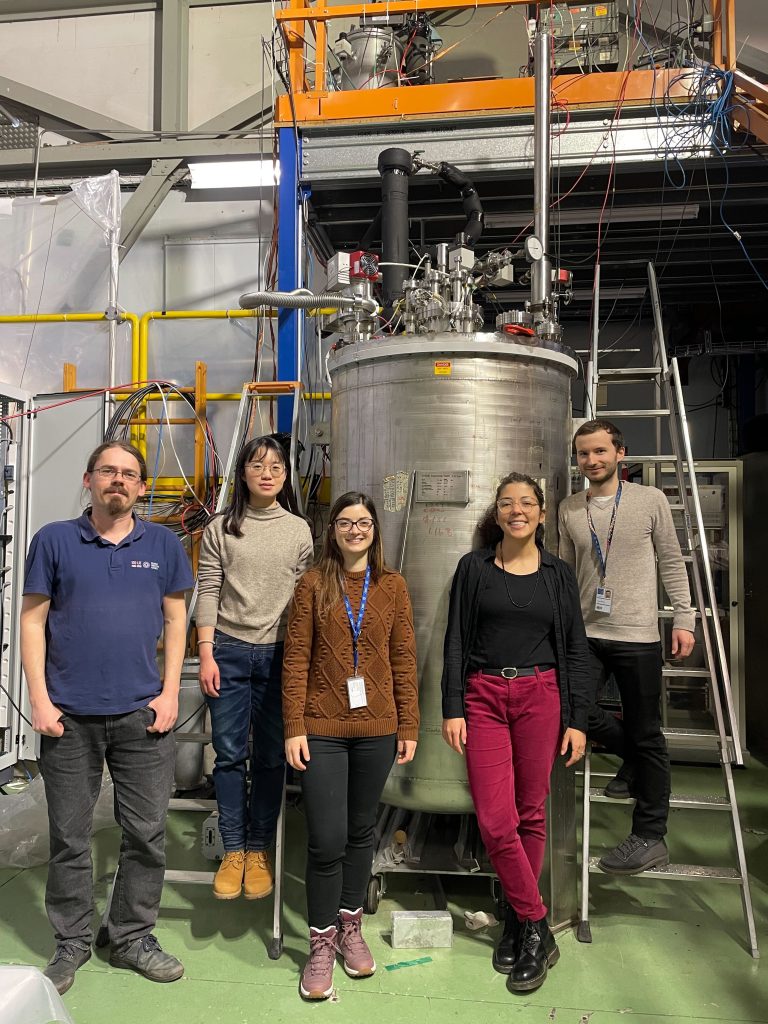

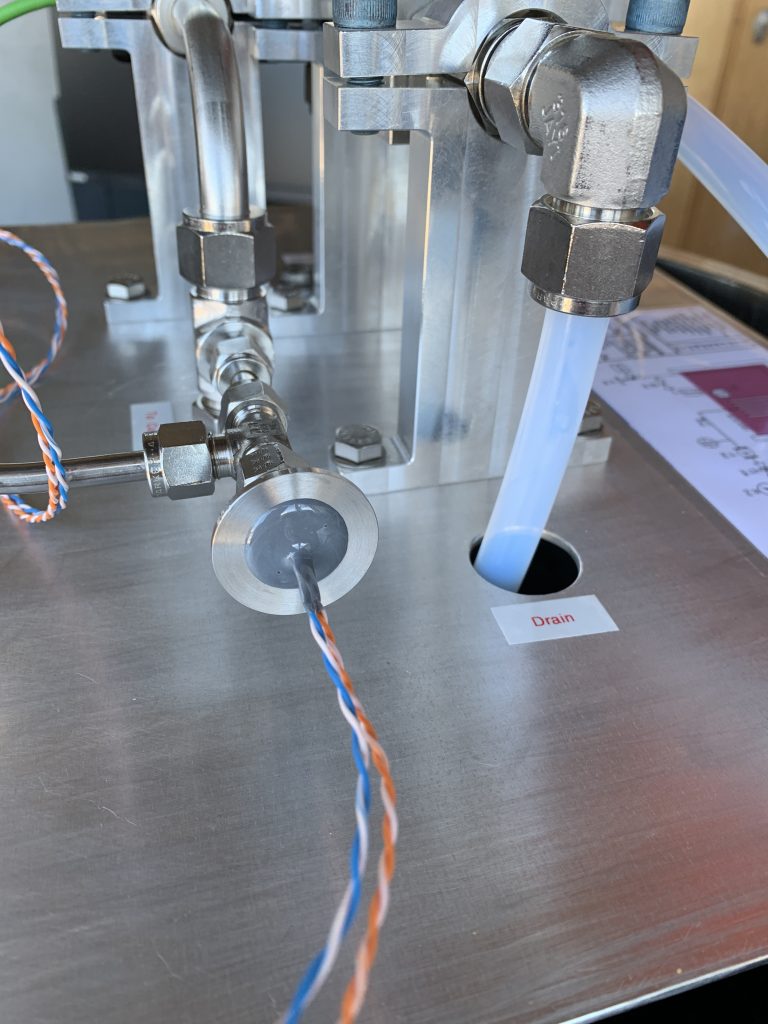

With the new year, we have entered the hot phase of assembling the mockup detector in our cleanroom at LNGS. Below are a few pictures of the components under my responsibility, which I assembled during multiple stays at LNGS over the past weeks. These days, our fantastic mockup team at LNGS is giving the detector its final touches!